Download these exclusively Free Weekly and Monthly Maintenance Log Templates prepared using MS Word and MS Excel to help you. You can also download Free Call Log Templates from our website.

When we talk about companies especially manufacturing plants, owners know how important it is to keep the plant running and how much it can cost if something breaks down and the product stops. Modern manufacturing plants are efficient with higher productivity but the problem is that each part of the process has major dependencies. This means if a machine breaks down, the entire production line comes to a stop. To ensure this doesn’t happen and the problem is checked and solved before it even happens, supervisors conduct weekly and monthly checkups of their equipment, and findings from each evaluation are recorded in the maintenance log.

Importance of Weekly and Monthly Maintenance Logs:

Keeping a maintenance log sheet can be beneficial from many perspectives. It’s similar to keeping track of your vehicle service so you know exactly when to take it to service when the oil will be changed, and when the tires are due for a change. Production plants and units conduct weekly maintenance of important and expensive equipment while keeping monthly maintenance for the less valuable or more durable machines. If the history of each checkup is kept in the permanent record, it increases the resale value of the machines. The new buyer will be happy to see that you have taken care of the equipment and there is no malfunction in it. Even if there was any problem, the maintenance log will indicate the issue and how it was resolved.

Periodic checkups of expensive equipment and keeping records of findings will help you save lots of money on equipment repair and replacement. When you do periodic maintenance and keep a log of the reports, it allows you to encounter a problem before it occurs. This way the damage can be kept to a minimum by replacing faulty parts before they cause further damage to other parts. Also, it will allow you to see a pattern over time about the equipment’s problems and wear and tear. You can evaluate if a problem keeps occurring due to misuse or improper training of the operator.

Workplace safety is a big concern for companies and production units. No employer wants to face a lawsuit just because they didn’t put safety measures for their staff and someone got hurt. When you do weekly or monthly maintenance of your equipment, it reveals safety issues as well as patterns in the damage. This way if an operator is not handling the machine properly, you can give him the training to handle the machine and allow him to work safely with heavy equipment.

Free Weekly and Monthly Maintenance Log Templates:

Here are previews and download links for these free Weekly and Monthly Maintenance Log Templates,

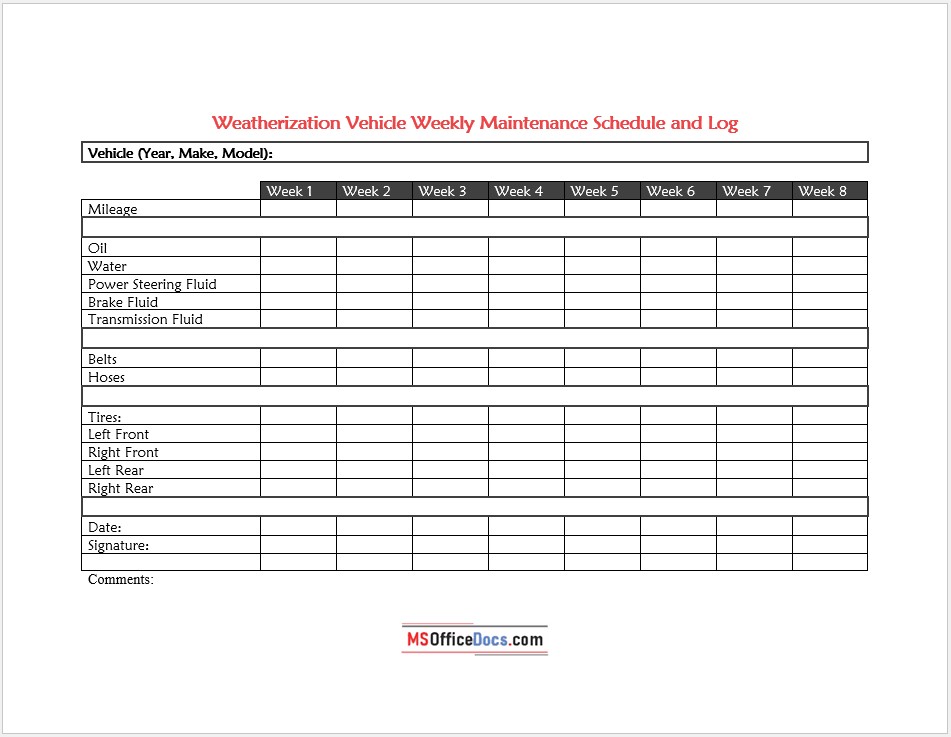

8 Weeks Vehicle Maintenance Log – MS Word Template

File Type: MS Word

File Size: 35 KB

Download Now

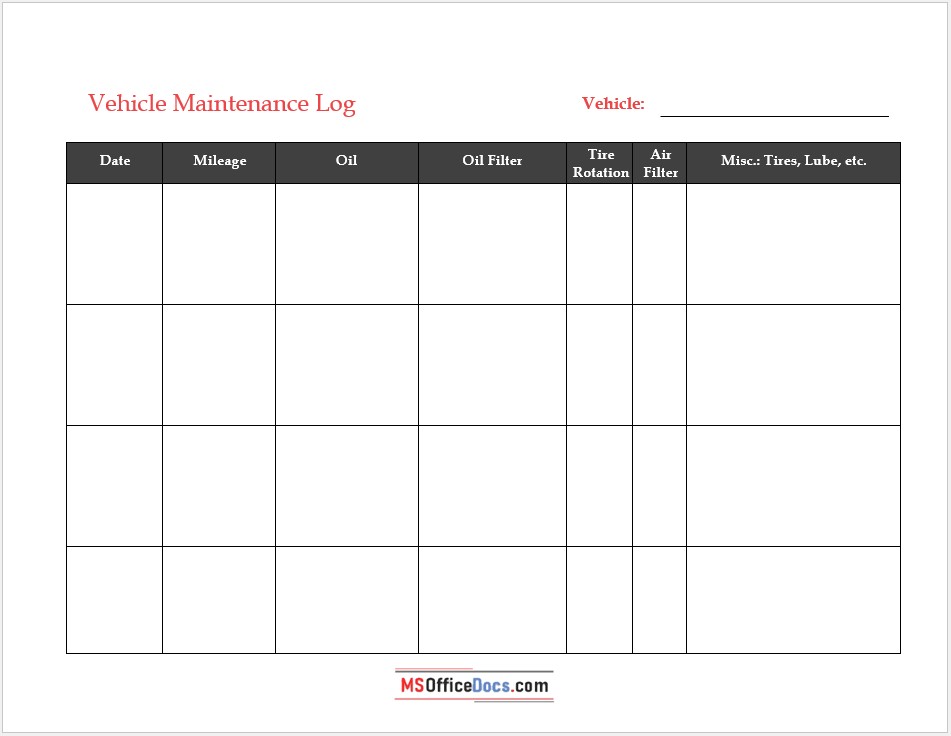

Simple Vehicle Maintenance Log – Editable Word Template

File Type: MS Word

File Size: 43 KB

Download Now

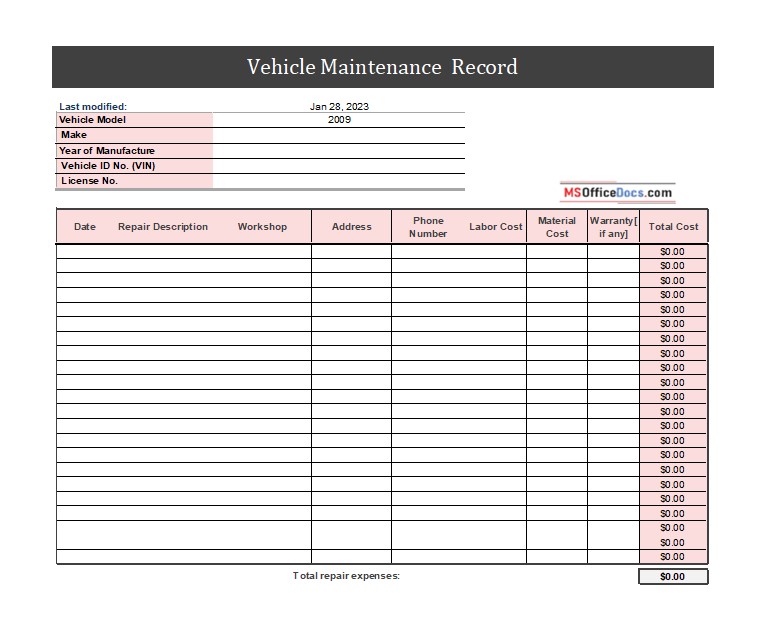

Detailed Vehicle Maintenance Log Excel

File Type: MS Excel

File Size: 21 KB

Download Now

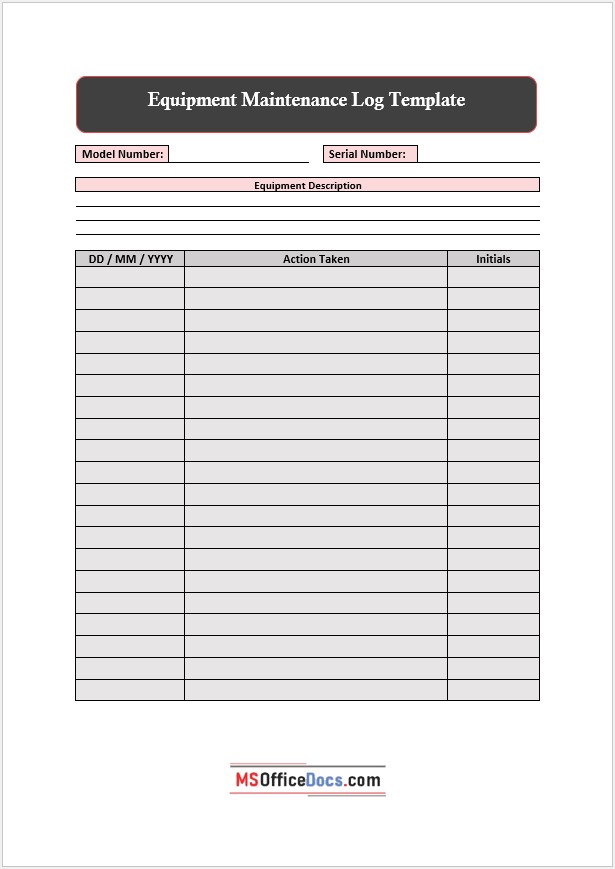

Equipment Maintenance Log – Editable Template

File Type: MS Word

File Size: 43 KB

Download Now

Guidelines to Create Maintenance Log:

- Add a description of the equipment:

Because there are dozens of important machines and equipment in any manufacturing plant, employers tend to keep separate maintenance log sheets for each machine. If this is the case, you should start creating the maintenance log by putting the description and details of the equipment or machine that you will inspect. This part should include everything from the name of the machine to its maker, its installation date, its warranty and service details, and most importantly, the role of the machine in the production process. - Mention the checkup period:

Some machines are expensive and delicate so they require frequent checkups i.e. once a week whereas, on the other hand, some machines are more durable so they can be inspected once a month. Your maintenance log sheet should indicate the inspection or maintenance period that you implemented for the machines. Also, the maintenance log should indicate when the last inspection was done. - Name of the inspector:

The person in charge of the inspection and evaluation should be mentioned properly in the maintenance log. There may be an entire team of inspectors and in that case, you should name each of the inspectors in the report. - Findings of the evaluation:

This part is the main portion of a maintenance log sheet because it includes the actual findings from the evaluation. The inspectors involved in the checkup can submit their reports or the supervisor can evaluate all the findings and compile a combined report for the maintenance log. If there is any problem with the equipment, it should be listed in the log. If the inspectors find out that the staff doesn’t have the proper training to operate the machine, the maintenance log should indicate it. - Recommendations:

At the end of the maintenance report, the inspectors should give their recommendations regarding the equipment and its maintenance. For instance, they can advise changing the spare parts more often or they can ask to contact the manufacturer for a problem that keeps occurring. This part mostly includes the solutions for the problems added in the findings section of the report.